TECHNOLOGY

Our 3D BioPrinted Tissue platform technology is built to scale and redefine the future of human tissue repair

DISCLAIMER:

Brinter’s 3D bioprinted tissue implants are investigational devices that have not yet been approved for commercial use in any country. The described design properties and intended purpose are subject to further validation.

APPLICATIONS

“We first aim to disrupt orthopedic and aesthetic repairs by applying our expertise in patient personalization.”

Orthopedic IMPLANTS

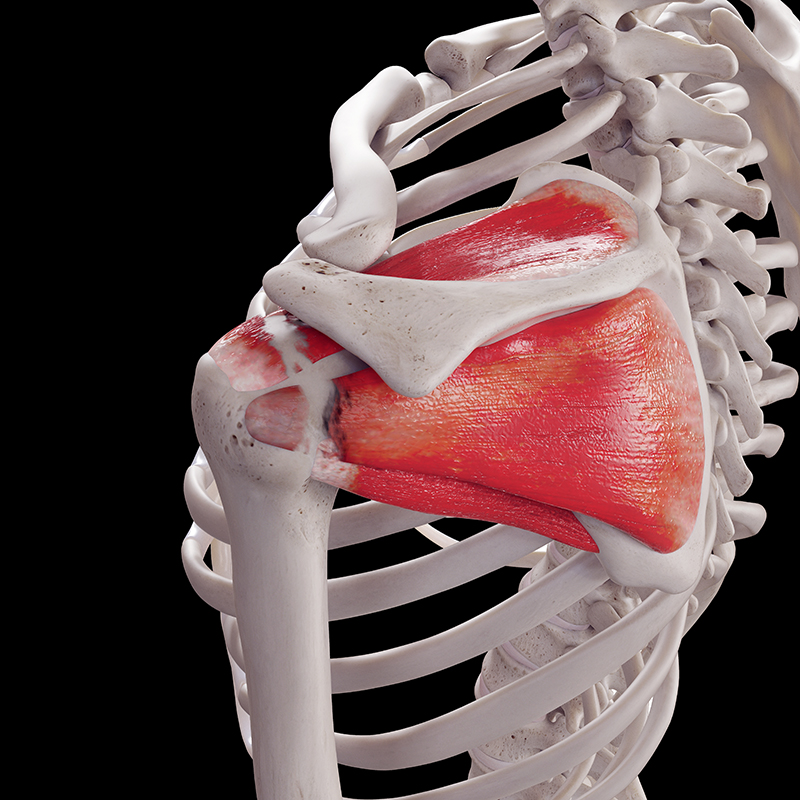

Rotator Cuff Repair

Our first implant targets rotator cuff repair, where nearly 50% of operations fail with regenerative materials and precise design.

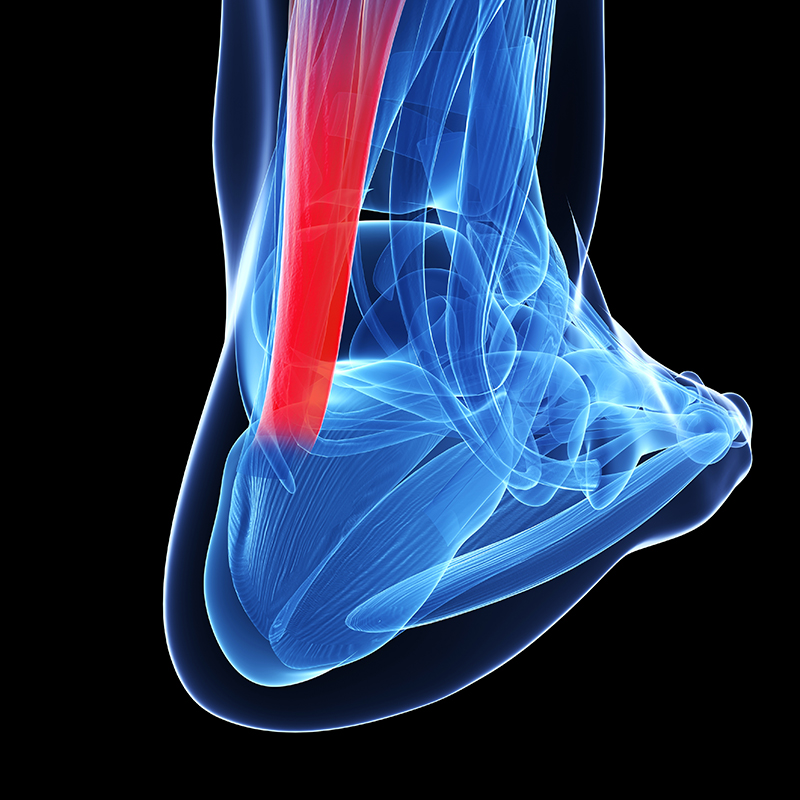

Achilles Tendon Repair

Achilles injuries take 9–12 months to heal, with few good treatments. Our regenerative implants aim to speed up and improve recovery.

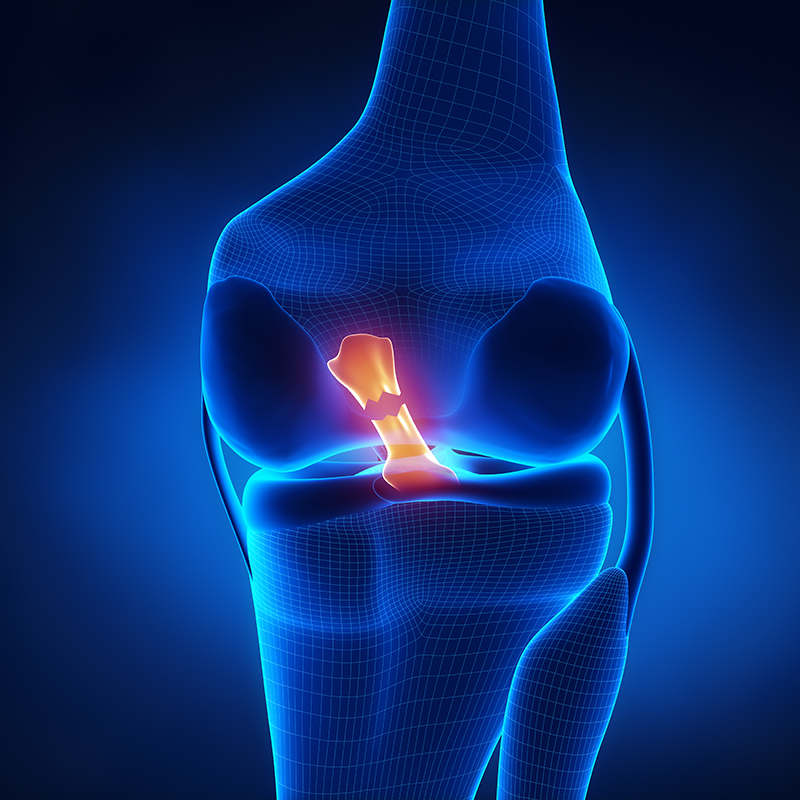

ACL Repair

We’re addressing key challenges like slow biological healing, long recovery times, high re-injury rates, and poor graft integration.

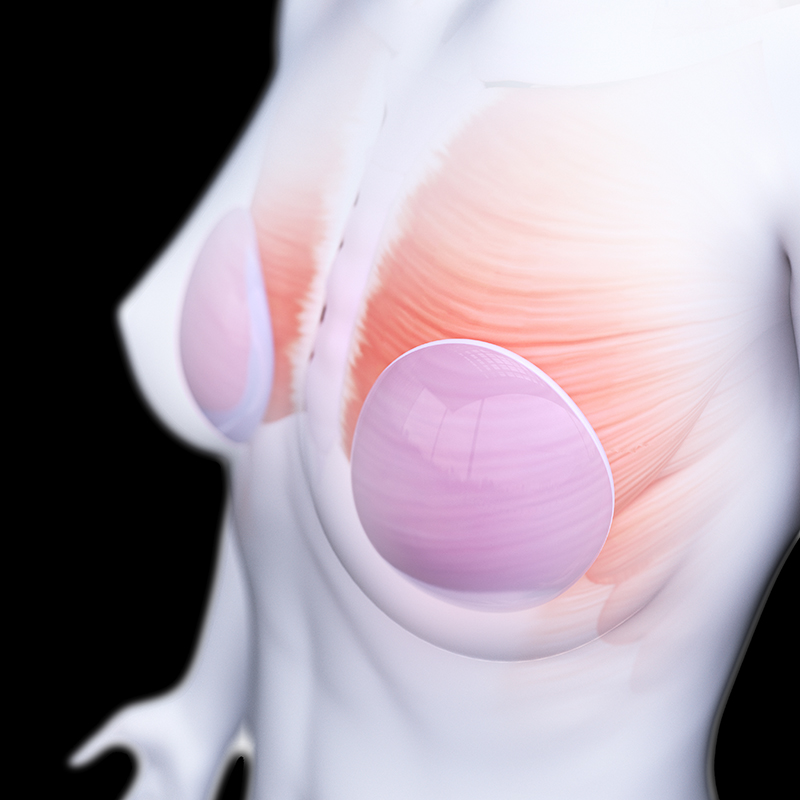

Aesthetic IMPLANTS

BREAST RECONSTRUCTIONS

3D BioPrinted implants for breast reconstruction enable natural tissue regeneration by guiding cell growth and vascularization, offering a safer, personalized alternative to synthetic implants.

FACIAL RECONSTRUCTIONS

E.g., 3D BioPrinted nasal implants mimic cartilage structure, support chondrocytes, and enable personalized, functional reconstruction.

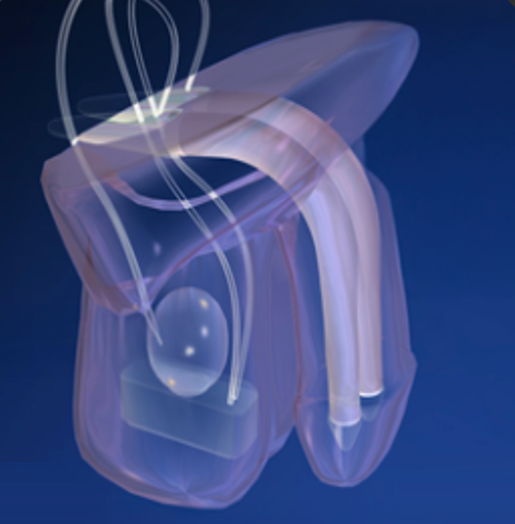

genital ReconstructionS

3D BioPrinted penile implants are designed to restore or reconstruct urogenital tissue, supporting improved outcomes in phalloplasty.

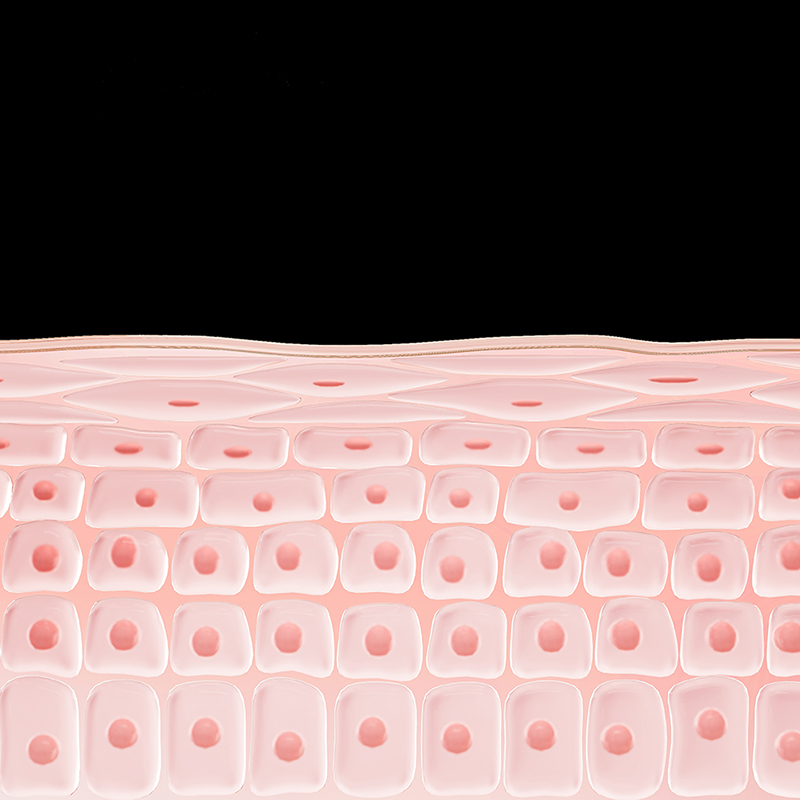

PERSONALIZATION

DESIGN AND MATERIAL PERSONALIZATION

3D bioprinted implants can be tailored in size and shape for better fit, function, and healing.

BIOLOGICS AND GROWTH FACTOR PERSONALIZATION

Customizing the implant’s biological components (proteins, peptides, or signaling molecules) to match a patient’s healing needs.

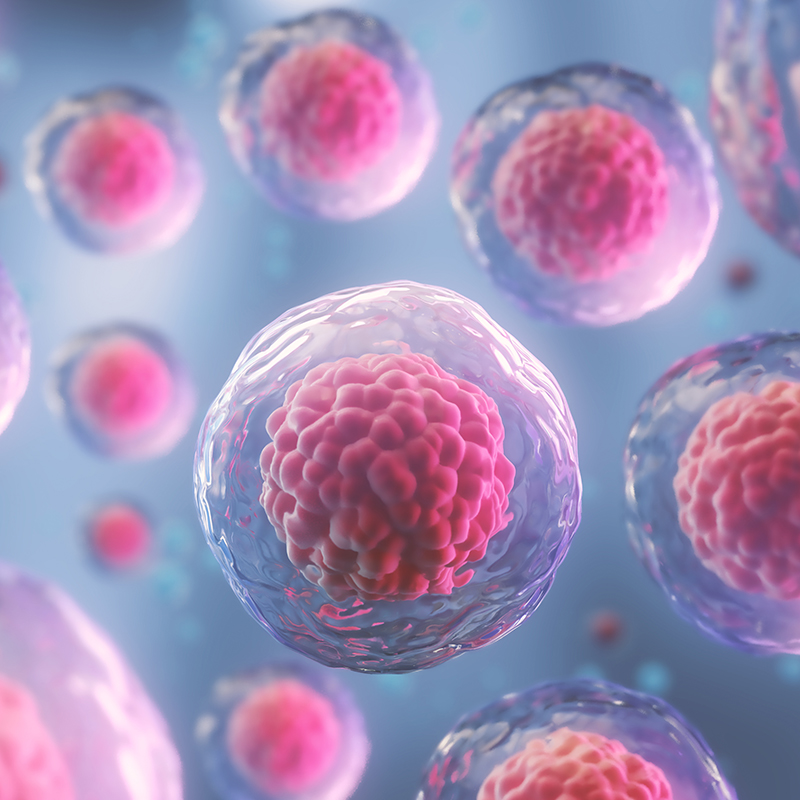

CELLULAR LEVEL PERSONALIZATIONS

Adding patient stem cells to bioprinted implants boosts regeneration, integration, and personalized healing.