Brinter has been developing the granulate-based multi-material 3D printing process as part of the EU Horizon2020 project Novum. The increased concern of environmental issues and technology development has led to growing interest in developing novel, sustainable, yet high-performance materials for industrial additive manufacturing (AM) and for a wide variety of applications such as electrical insulation components and parts for the automotive, marine and medical industry. AM enables rapid and cost-effective manufacturing of complex and lightweight parts without any expensive tools such as moulds.

Most of the home 3D printing systems use filaments. Thermoplastic materials in the form of pellets or granules have several advantages over filaments, especially in industrial systems. By using granules, high flow rates and large area prints can be achieved, and a greater variety of materials become available for printing. Also, the material processing costs are lowered as filament extrusion, and spooling phases can be skipped altogether.

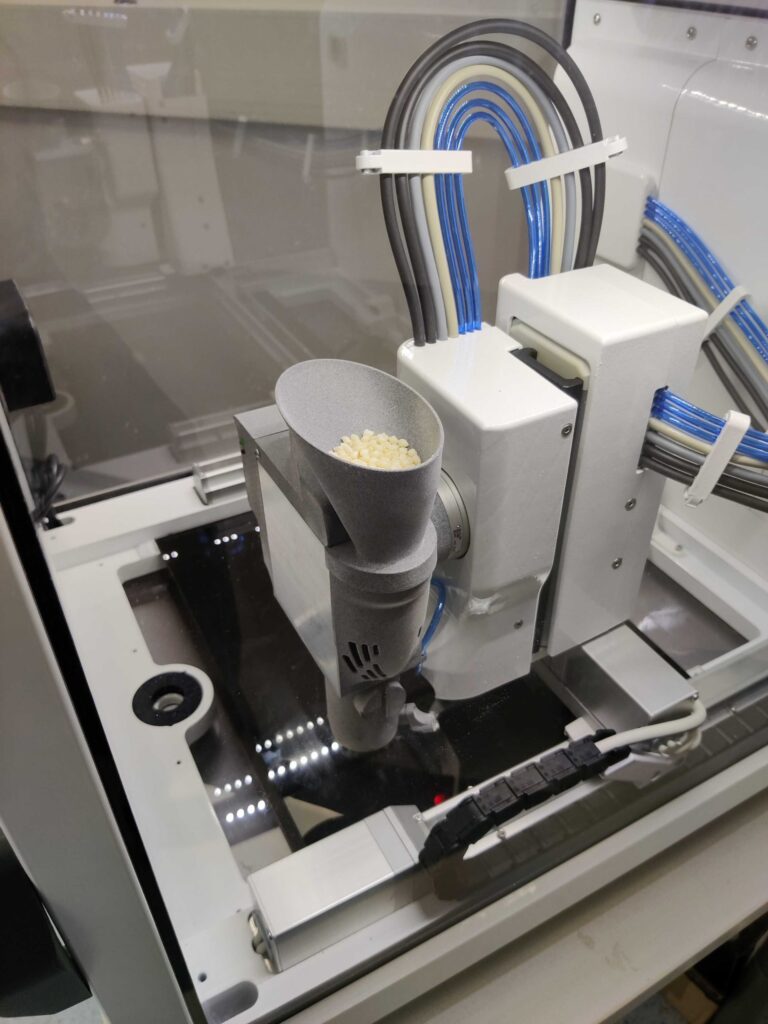

Brinter’s Granu Tool print head utilizes granulate printing process and allows 3D printing of various thermoplastics, such as Polylactic acid (PLA) and Polycaprolactone (PCL). Even renewable and abundantly available cellulose-based composites can be successfully printed with the Granu Tool if the composite’s composition is carefully tuned, such as in the recent VTT’s scientific article entitled “Thermoplastic Cellulose-Based Compound for Additive Manufacturing” by Immonen, K. et al.

Granulate printing can also be combined with other available print heads in our modular Brinter® 3D bioprinting platform to enable genuine multi-material printing of materials ranging from pastes and gels incorporating living cells to plastic granulates or metal injection moulding (MIM) materials.

Our screw extrusion-based granulate printing technology can also be used for printing polymer-based drug delivery formulations utilized in pharmaceutical studies and development. Einari Tolvanen has performed one such research case in his Bachelor’s thesis entitled “Suitability Of Screw Extrusion 3D-Printing Tool for Polymer-Based Drug Formulation”, which is currently unfortunately available only in Finnish.