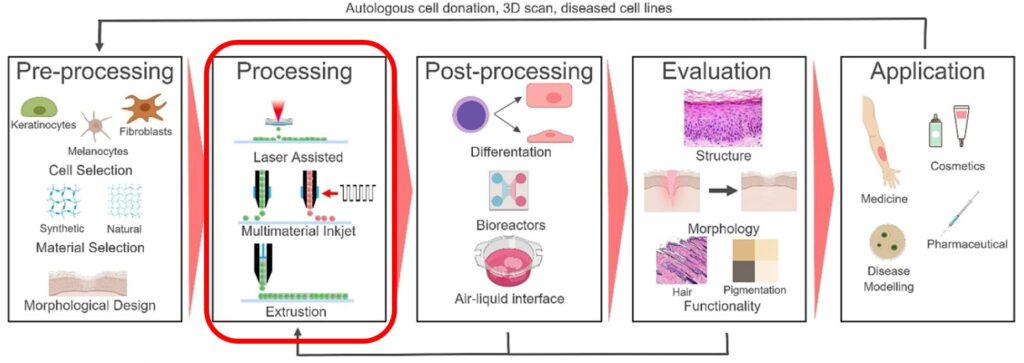

This article deals with the actual printing step of the 3D bioprinting process by focusing on different bioprinting technologies. The upcoming articles will cover optimization of printing parameters, crosslinking of printed structures, and post-printing evaluation. The cover picture of this article shows an example of 3D Bioprinting process steps (source: Regenerative Medicine Frontiers Journal article: Regen Med Front. 2019;1:e190004).

The three basic steps in the 3D bioprinting process include:

- Pre-printing/pre-processing. This includes the selection of cells and bioink materials, mixing of the ingredients, and creating the 3D design. (This step is covered in the previous article)

- Bioprinting using one or more of the available printing technologies to bioprint a tissue construct and crosslinking to maintain a stable structure. (The focus of this particular part article)

- Post-printing. This phase includes the cultivation of the tissue structure in a bioreactor. The printed construct is then mechanically tested and evaluated. Finally, the construct can be used for the intended application. (These steps will be covered in our future blog articles)

The 3D bioprinting process involves depositing the bioink layer-by-layer, where each layer has a thickness of 0.5 mm or less. Several different bioprinting techniques have been developed, although most commercial bioprinters utilize extrusion-based printing. All techniques have their own pros and cons as well as requirements for the bioink properties.

3D bioprinting techniques can be classified into three different categories according to their working principle: extrusion-, droplet-, and laser-based bioprinting.

Figure 1. Different bioprinting techniques and their working principles. (A) Extrusion-based bioprinting (EBB) systems are driven by either air pressure, a piston, or a rotating screw. Instead of droplets, a continuous filament of bioink is dispensed. (B) Thermal and piezoelectric drop-on-demand (DOD) inkjet printing systems. In thermal DOD printers, the thermal actuator heats the bioink solution creating vapor bubbles, which in turn generate pressure pulse and force droplets out of the nozzle. In piezoelectric DOD printers, an actuator changes its shape producing a pressure wave, which ejects the bioink droplet. (C) Laser-induced forward transfer (LIFT) system, in which the laser is focused on an absorbing intermediate layer creating a vapor bubble. As the bubble expands, a jet of bioink is formed transferring bioink droplets onto a substrate. (Source: AIMS Cell and Tissue Engineering, 2(3): 119–162.)

In general, EBB is a very versatile and affordable printing method, and it has greater deposition and printing speed than other methods, which facilitates the scalability of the technique. Also, several commercial EBB printers are already available. EBB is the only bioprinting method allowing printing of high cell densities with reasonably small process-induced cell damage. However, the resolution of the EBB technique is very limited as the minimum feature sizes are generally over 100 µm, which is considerably inferior to other bioprinting techniques, especially laser-based bioprinting.

DOD inkjet printing systems are able to print with high resolution (10-50 um) using high printing speed (up to 10 000 droplets/s). They even enable the printing of cell concentration gradients. However, only low viscosity inks can be used in inkjet printing to prevent clogging, and there is some difficulty in printing vertical 3D structures.

Laser-based bioprinting systems (LBB) are capable of fabricating highly accurate tissue constructs, but the intricate setups have limited the commercialization; currently, there exists only one company worldwide using LBB for the fabrication of tissues. As nozzle-free approaches, LBB techniques circumvent several limitations that EBB and DBB techniques face, such as shear stress-induced cell damage or nozzle clogging. The major advantage of LBB is its high resolution, being below 10 µm in its best. Despite the high resolution, processes based on photopolymerization suffer from prolonged fabrication times, the interaction of cells with damaging laser light, expensive setup prices, and lack of photocrosslinkable bioink choices. On the other hand, cell transfer-based processes (such as LIFT) face challenges due to laser shock-related thermal- and mechanical-induced cell deformation, the random placement of cells in the precursor solution, and expensive fabrication setups.

What is Bioprinting – Part 4 of 6

In the next article on What is Bioprinting, we learn about the optimization of several printing parameters in order to achieve a good resolution and repeatability. So, stay tuned, the story will be continued…