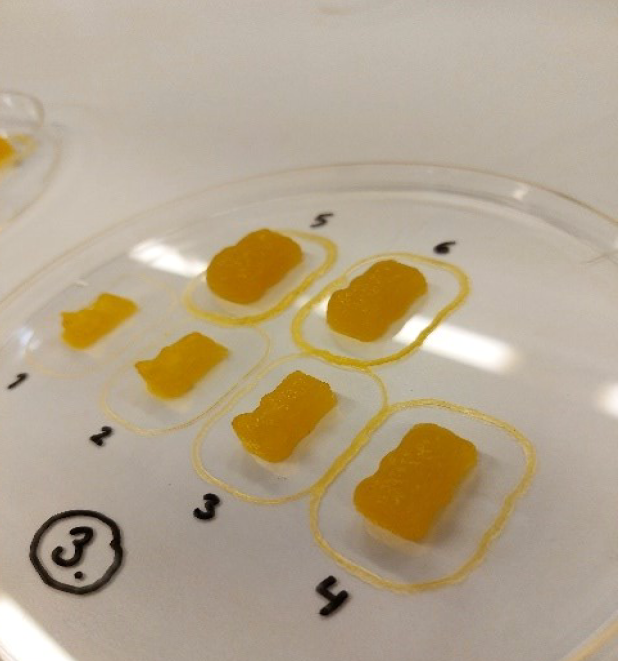

In a recent Bachelor’s thesis by Emma Hentunen, working instructions on 3D printing food such as marmalade with a Brinter® One bioprinter were prepared for teaching and learning purposes at Turku University of Applied Sciences. First, marmalade was prepared from 5 w-% gelatin and fruit butter. Gummy bear test structures were printed using a Pneuma Tool print head at room temperature using a 0.41 mm nozzle.

Marmalade is quite unpredictable as a printing material. Hence the printing method development had to take into account the effects of temperature on the coagulation of marmalade. As the marmalade softens at room temperature during printing, the softening must be compensated by lowering the printing pressure.

Both the printing method and the working instructions remain to be developed further in the future, but the obtained results still provide a valuable basis for the subsequent 3D printing food experiments with marmalade.