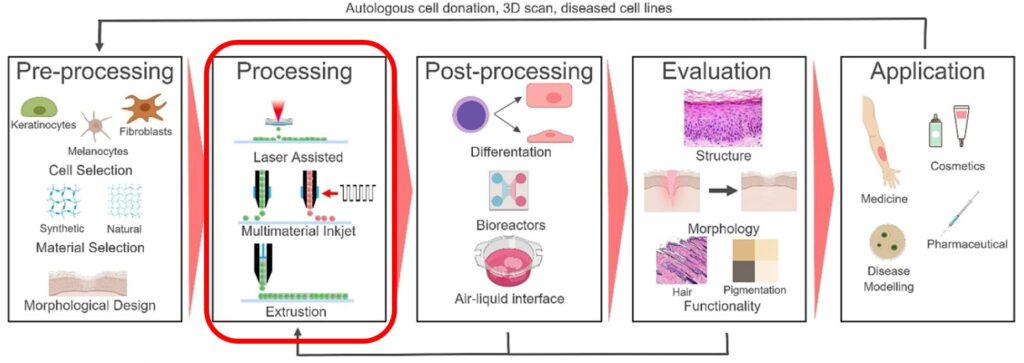

This article summarizes the different crosslinking approaches to solidify the printed bioink into a stable structure. The upcoming part will cover the post-printing evaluation of the fabricated structures. The cover picture of this article shows an example of 3D Bioprinting process steps (source: Regenerative Medicine Frontiers Journal article: Regen Med Front. 2019;1:e190004).

The three basic steps in the 3D bioprinting process include:

- Pre-printing/pre-processing. This includes the selection of cells and bioink materials, mixing of the ingredients, and creating the 3D design. (This step was covered in the previous article).

- Bioprinting using one or more of the available printing technologies to bioprint a tissue construct and crosslinking to maintain a stable structure. (Part of this step was covered in the previous articles, and the crosslinking is covered here).

- Post-printing. This phase includes the cultivation of the tissue structure in a bioreactor. The printed construct is then mechanically tested and evaluated. Finally, the construct can be used for the intended application. (These steps will be covered in our future article).

During the process of 3D bioprinting, the polymer solution is transformed into a 3D structure via crosslinking. Crosslinking is a crucial step that significantly influences the mechanical and physicochemical characteristics of the bioprinted constructs and the cellular behavior of the incorporated cells in the bioink. Depending on the nature of the polymeric backbone and functional groups present in the prepolymer, hydrogel bioinks can be crosslinked using various methods that can be chemical, physical, enzymatic or a combination of them.

In the chemical crosslinking approach, the network is formed via nonreversible covalent bonding between polymeric chains. Covalent bond is an interatomic linkage that results from the sharing of an electron pair between two atoms. Covalent bonding can be achieved either by adding chemical crosslinkers (e.g., sodium bicarbonate or thrombin) or through various chemical reactions, including Schiff base chemistry, thiolene coupling, enzymatic crosslinking, or photocrosslinking using ultraviolet (UV), visible, or near-infrared light. These chemically formed hydrogels are usually strong enough to provide proper shape stability, but crosslinking kinetics should be precisely controlled to avoid any printer nozzle blockage.

Photocrosslinking is an exciting option for 3D bioprinting, too, as many 3D printing industries have been using this method to fabricate their products. Light is minimally invasive, and by spatiotemporally controlling its application, it is possible to crosslink the bioink locally and on-demand. In addition to extrusion bioprinting, there are several other 3D bioprinting techniques leveraging different photocrosslinking schemes such as stereolithography, digital light processing, and laser-assisted methods. The principle of all these methods is based on using photocurable bioinks (together with photoinitiators) that can be crosslinked through either chain-growth mechanisms, step-growth mechanisms, or redox-based reactions.

The choice of photoinitiator is critical in photocrosslinking-based bioprinting because the absorption peak of the initiator determines the wavelength of light which must be applied to the bioink. This wavelength is known to have a direct impact on cell viability. The use of UV light for photocrosslinking may damage cells’ DNA in the printed constructs and can potentially be harmful to the operators as well. Hence, the use of visible light, such as blue light at 405 nm, is considered advantageous because the wavelengths of the visible range are not detrimental to cells.

Physical crosslinking methods are based on the formation of noncovalent bonds, such as hydrogen bonds, hydrophobic interactions, electrostatic attraction and ionic crosslinking. Noncovalent bonds are relatively weak bonds formed between molecules without sharing electrons. It can be thought of more as an attraction than a bond because they’re “easily” reversible. Physically crosslinked hydrogels are usually mechanically weak but provide a more cell-friendly environment than chemically crosslinked hydrogel.

Ionic interaction is one of the most common methods used physical crosslinking method. It usually involves the addition of multivalent cations to the polymer solution to induce gelation. In this rapid crosslinking method, hydrogels can be formed under mild conditions at room temperature and physiological pH, making it an attractive approach for crosslinking. However, it has some drawbacks, such as mechanical weakness, poor stacking ability, and the possibility of releasing metal ions into the body after implantation. Ionic interaction via Ca2+ ions is mainly used as a crosslinking strategy in the 3D bioprinting of sodium alginate.

In addition to the type of crosslinking approach, also crosslinking density plays an essential role in 3D bioprinting. One must find a compromise between the degree of crosslinking and printability, as lower crosslinking density may enable faster bioink flow but poor shape fidelity. On the contrary, a higher crosslinking degree may lead to stiffer gel with better stability but can hamper the printability.

What is Bioprinting – Part 5 of 6

In the next article on What is Bioprinting, we learn about different post-printing processes to analyze the printed construct’s structure, morphology and functionality.

This article is based on the following review articles:

GhavamiNejad A, Ashammakhi N, Wu XY, Khademhosseini A. Crosslinking Strategies for 3D Bioprinting of Polymeric Hydrogels. Small. 2020 Sep;16(35):e2002931. doi: 10.1002/smll.202002931.

Knowlton S, Yenilmez B, Anand S, Tasoglu S. Photocrosslinking-based bioprinting: Examining crosslinking schemes. Bioprinting. 2017 March;(5):10-18 doi:10.1016/j.bprint.2017.03.001.